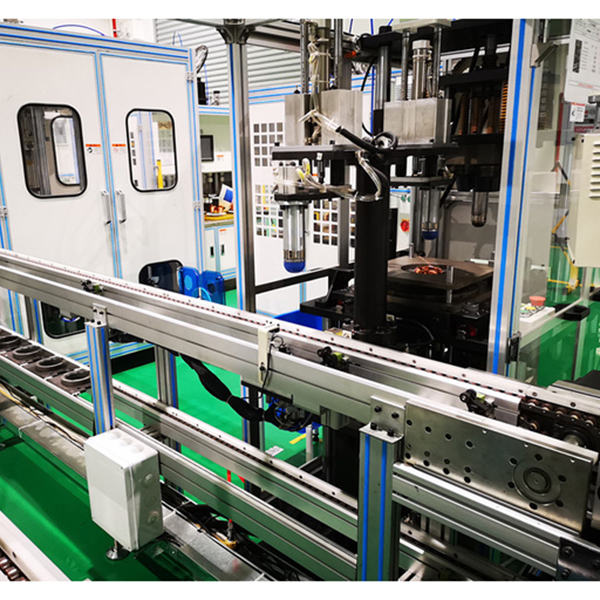

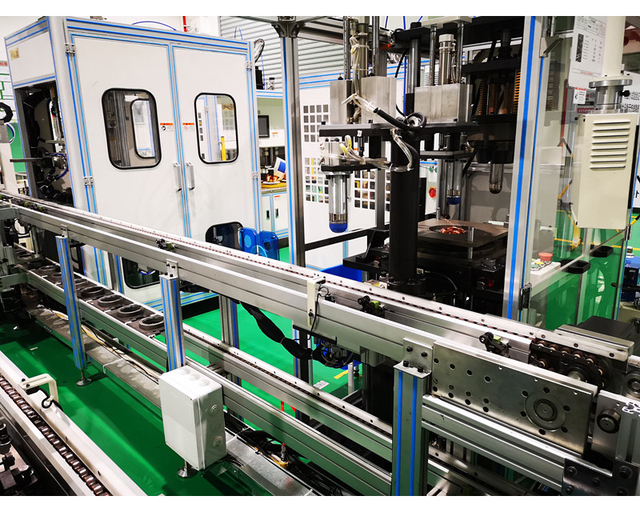

Ulayini wokukhiqiza othomathikhi we-Stator (imodi ye-speed chain 2)

Incazelo Yomkhiqizo

Ulayini wokukhiqiza othomathikhi udlulisela ithuluzi ngomugqa wokuhlanganisa we-double speed chain, (okuhlanganisa ukufakwa kwephepha, ukusonga, ukushumeka, ukubunjwa okuphakathi, ukubopha, ukuqeda nezinye izinqubo) ngokuma okunembile nokusebenza okuzinzile nokuthembekile.

Isakhiwo

Ungalungisa kanjani umshini wokushisela we-rotor othomathikhi we-rotor?

I-rotor automatic line spot welder ekuqaleni yayifakwe isilawuli se-AC kanye ne-AC spot welder, kodwa amandla amanje angazinzile we-AC spot welder nenkinga yokushisela okubonakalayo kubangele ukuthi kushintshwe isilawuli se-DC esishintshashintshayo esiphakathi, i-intermediate frequency inverter, kanye ne-spot welder. Kulesi sihloko, sizoxoxa ngezindlela ezihlukahlukene zokulungisa okwamanje we-rotor wire spot welder:

1. Ukulawula imodi yamandla njalo: Ukusebenzisa imodi yamandla engaguquki Q=UI ingagwema ukukhuphuka kwe-electrode resistivity kanye nezinga lokushisa uma usebenzisa imodi yamanje engaguquki, futhi ivimbele i-thermal Q=I2Rt ekukhuphukeni. Ngokusebenzisa imodi ethile yamandla engu-Q=UI, ukushisa kungaba nokulinganisela.

2. Ukulinganisa i-voltage yomugqa othomathikhi we-rotor ezimbili: isilinganiso se-voltage kufanele senziwe eduze kakhulu nezigxobo ezinhle nezimbi. Iphuzu liwukulawula inani le-voltage phakathi kwezigxobo ezinhle nezingezinhle, hhayi i-voltage yesifunda sonke.

3. Shintsha kusuka ku-1-pulse discharge kuya ku-2-pulse discharge noma i-3-pulse discharge (isikhathi sokukhipha isamba sihlala singashintshiwe), futhi unciphise inani lamandla (noma inani lamanje) libe lincane. Uma kusetshenziswa ukukhishwa kwe-pulsed, inani lamandla lizodinga ukukhushulwa ukuze kuzuzwe ukushisa okufunayo. Uma kusetshenziswa ukukhishwa kwe-pulse kabili (inani lokuqala lokukhishwa kwe-pulse libekwe phansi, futhi inani lokukhishwa kwe-pulse yesibili libekwe phezulu), inani lamandla (noma inani lamanje) lingancishiswa kakhulu ekushiseleni. Ukuncipha kwevelu yamandla (noma inani lamanje) kubangela ukuguga okuncishisiwe kwama-electrode kanye nokuzinza kwe-welding okuthuthukisiwe. I-Q=I2Rt isho ukuthi ukunqwabelana kokushisa kuthinteka kakhulu ngokwenyuka kwevelu yamanje. Ngakho-ke, lapho usetha amapharamitha, yehlisa inani lamanje (noma inani lamandla) libe lincane.

4. Faka esikhundleni i-electrode ye-tungsten ku-hook ngaphansi kwendawo yokushisela nge-electrode engalungile, ngoba i-current igeleza isuka ku-hook iye ku-electrode ye-tungsten, okubangela "ukunyakaza kwe-electron", okuholela ekutheni ama-athomu ensimbi amancane ageleze ku-electrode, ayenze ingcolile futhi iphelelwe amandla. "Ukunyakaza kwe-elekthronikhi" kusho ukuthi ukugeleza kwama-electron e-valence yensimbi kubangela ukunyakaza komzimba owuketshezi oqukethe ama-athomu ensimbi.

Ngokwendlela engenhla, ukulungiswa kwamanje komshini wokushisela we-rotor othomathikhi we-wire spot kungaqedwa ngempumelelo. Lesi sihloko sihlose ukuqonda kangcono ukusetshenziswa kwe-electromechanical of rotor automatic wire spot welders ukuthuthukisa ukusebenza kahle kokukhiqiza nokonga amandla. Ukwengeza, ukugcinwa njalo kwesimiso kufanele kuhlanganiswe nokusebenza kwemigqa yokukhiqiza i-rotor ezenzakalelayo. Lokhu kunomthelela ekuphileni kwayo isikhathi eside kanye nokunemba kokusebenza kwayo.