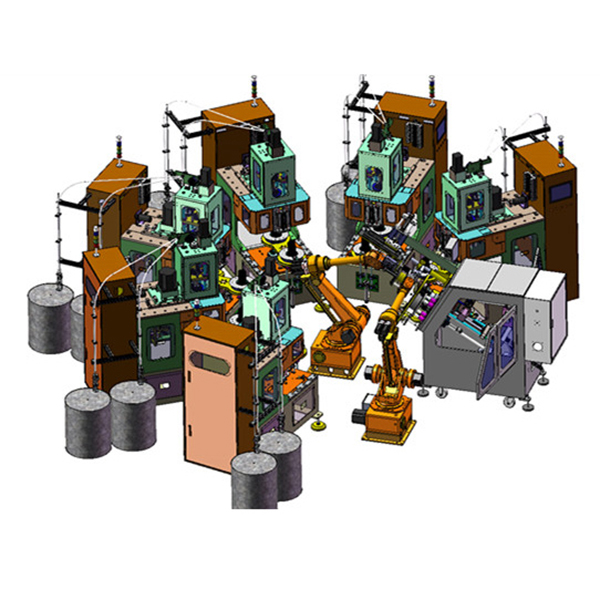

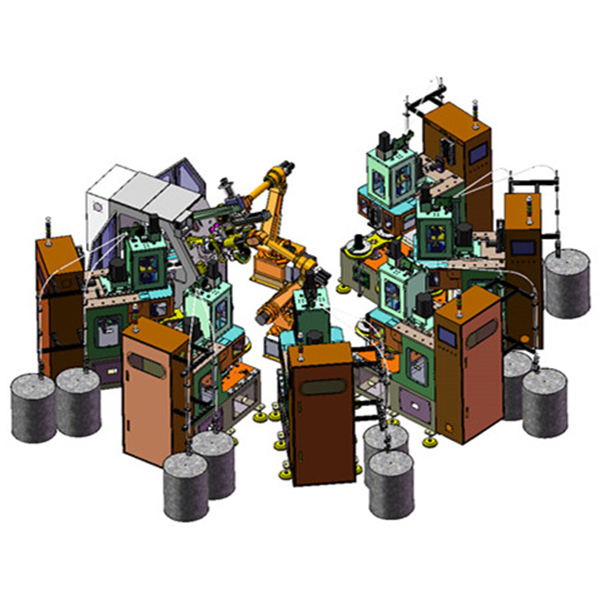

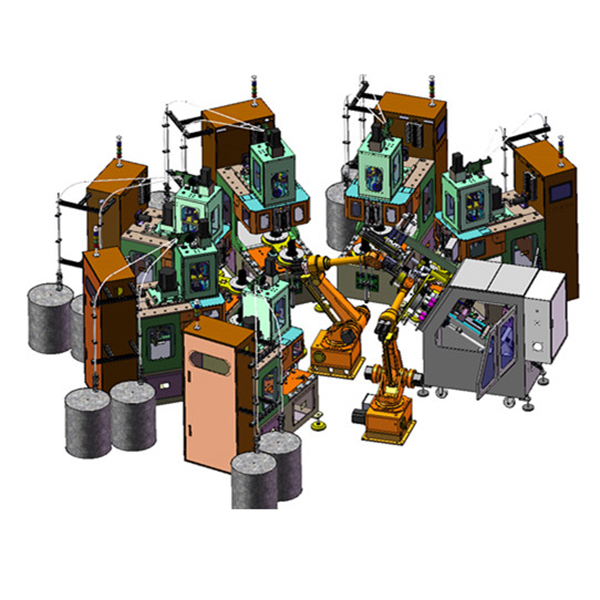

Ulayini wokukhiqiza we-Motor stator othomathikhi (imodi yerobhothi 2)

Incazelo Yomkhiqizo

● Irobhothi lisetshenziselwa ukudlulisa amakhoyili omshini ovunguzayo oqondile kanye nomshini ojwayelekile wokufaka i-servo wire.

● Ukulondoloza umsebenzi wokusebenza kwezintambo ezisongayo nezifakayo.

Isakhiwo

Izixazululo zezinkinga ezivamile ngemva kokuhlanganisa ulayini we-rotor othomathikhi

I-rotor automatic line assembly iyisisetshenziswa esizenzakalelayo esakhiwe ama-actuator, izakhi zezinzwa, nezilawuli.Amaphutha emugqeni womhlangano ozenzakalelayo we-rotor angaholela ekusebenzeni okuguquguqukayo noma okungasebenzi ngokuphelele.Kulesi sihloko, sixoxa ngezindlela ezine ezivamile zokuhlonza amaphutha emigqeni yokuhlanganisa ye-rotor ezenzakalelayo.

1. Yenza ukuhlolwa okuphelele kokuphakelwa kukagesi, umthombo womoya, kanye nempahla yomthombo we-hydraulic ekuhlanganiseni kolayini ozenzakalelayo we-rotor.Iningi lezinkinga zomugqa wokuhlanganisa othomathikhi we-rotor zivela ezinkingeni zokunikezwa kwamandla kagesi, umthombo womoya kanye nomthombo we-hydraulic.Lapho uhlola, qiniseka ukuthi ukunikezwa kwamandla kweshabhu kwanele nokuthi zonke izinto zokusebenza zisebenza ngokujwayelekile.Hlola umthombo womfutho womoya kanye nepompo ye-hydraulic edingekayo kuma-hydraulic omugqa wokuhlanganisa.

2. Hlola ukuthi isikhundla senzwa kumhlangano we-rotor othomathikhi sishintshile.Ngokuhamba kwesikhathi, izinzwa zingase zibe nezinkinga zokuzwela, ukungasebenzi kahle, noma ukushintsha indawo.Indawo yokuthola nokuzwela kwenzwa kufanele ihlolwe njalo, ilungiswe kahle uma isimo sishintsha, futhi kufakwe esikhundleni ngokushesha lapho yehluleka.Izinkinga zokudlidliza ngesikhathi sokusebenza komugqa womhlangano onyakazayo nazo zingadala izinzwa ezixegayo.Kubalulekile ukuqinisekisa ukuthi inzwa isendaweni eqinile.

3. Hlola i-relay, i-valve yokulawula ukugeleza kanye ne-valve yokulawula ukucindezela.Umsebenzi we-relay ufana nalowo wenzwa yokungenisa kazibuthe, futhi izinkinga zesikhathi eside zokumisa phansi zizothinta ukusetshenziswa okuvamile kwesekethe futhi zidinga ukushintshwa.Isistimu ye-pneumatic noma ye-hydraulic yomugqa wokuhlanganisa, ukuvulwa kwe-valve ye-throttle, intwasahlobo yokulungiswa kwengcindezi ye-valve yokucindezela, njll izolahlekelwa ukuqina noma ukushelela ngenxa yezinkinga zokudlidliza, futhi idinga ukugcinwa njalo ngesikhathi sokusetshenziswa okuvamile.

4. Hlola ukuxhunywa kwesekethe kagesi, yomoya kanye ne-hydraulic.Uma ukuhlola indawo enephutha kungavezi umthombo wenkinga, hlola isimo sesekhethi yedivayisi ukuze uthole isekethe evuliwe.Qinisekisa ukuthi amakhondatha ezintambo zikagesi awashintshile ngenxa yezinkinga zokuphuma futhi uhlole i-bronchus ukuze uthole noma yimuphi umonakalo noma imibimbi.Hlola ukuthi isifunda sawoyela we-hydraulic sivimbekile yini.Uma i-trachea ishwabene kakhulu, kufanele ishintshwe ngokushesha.Uma kunenkinga ngepayipi likawoyela we-hydraulic, kuzodingeka futhi lishintshwe.

5. Uma izimo ezingenhla zingekho, amathuba ezinkinga zohlelo kusilawuli somugqa we-rotor othomathikhi aphansi kakhulu.